WHILE WE ORIGINALLY BUILT our reputation on all-season tents, we have always known that there were many users who wanted a lighter weight tent, and who didn’t need all-season strength and comfort. But we have never subscribed to the traditional concept of “3 season tents,” which always seemed to equate to “summer tents.” In part, the problem is that those three seasons – spring, summer, and fall – are very different in, say, northern Sweden, than they are in Australia.

In 2010, we began the project that would become our Yellow Label tents, which we introduced in 2012. Rather than creating the typical “3-season tents,” however, we set out to build lighter weight tents that would work well in more protected terrain but in all types of weather during the warmer, snow-free months of the year, regardless of geographic locale.

With the goal of maximizing light weight without sacrificing too much strength, we experimented with a variety of solutions. Initially, we put the poles on the inner tent, but still with a linked outer tent. After a number of such test tents literally flattened during wind testing, we adopted our proven system of linked but separable inner and outer tents, with the poles on the outer. This solution performed so much better, that we knew it was the ideal choice for these tents.

During this process, we also discovered that the weight savings from using smaller than 9 mm diameter poles – the same type of poles found in our Red Label, all-season tents – was slight, while the loss of strength was substantial. So, again, we stayed with the proven solution – 9 mm DAC NSL poles.

We did use lighter weight fabrics, in both inner and outer tents. For the outer tent, we developed Kerlon 1000. We knew that warmer weather, snow-free use does not place the same stress on a tent that true, all-season use does, but we still needed to maintain enough strength for heavy rains and windy conditions. Kerlon 1000 boasts a substantial 8 kg/17.6 lb tear strength.

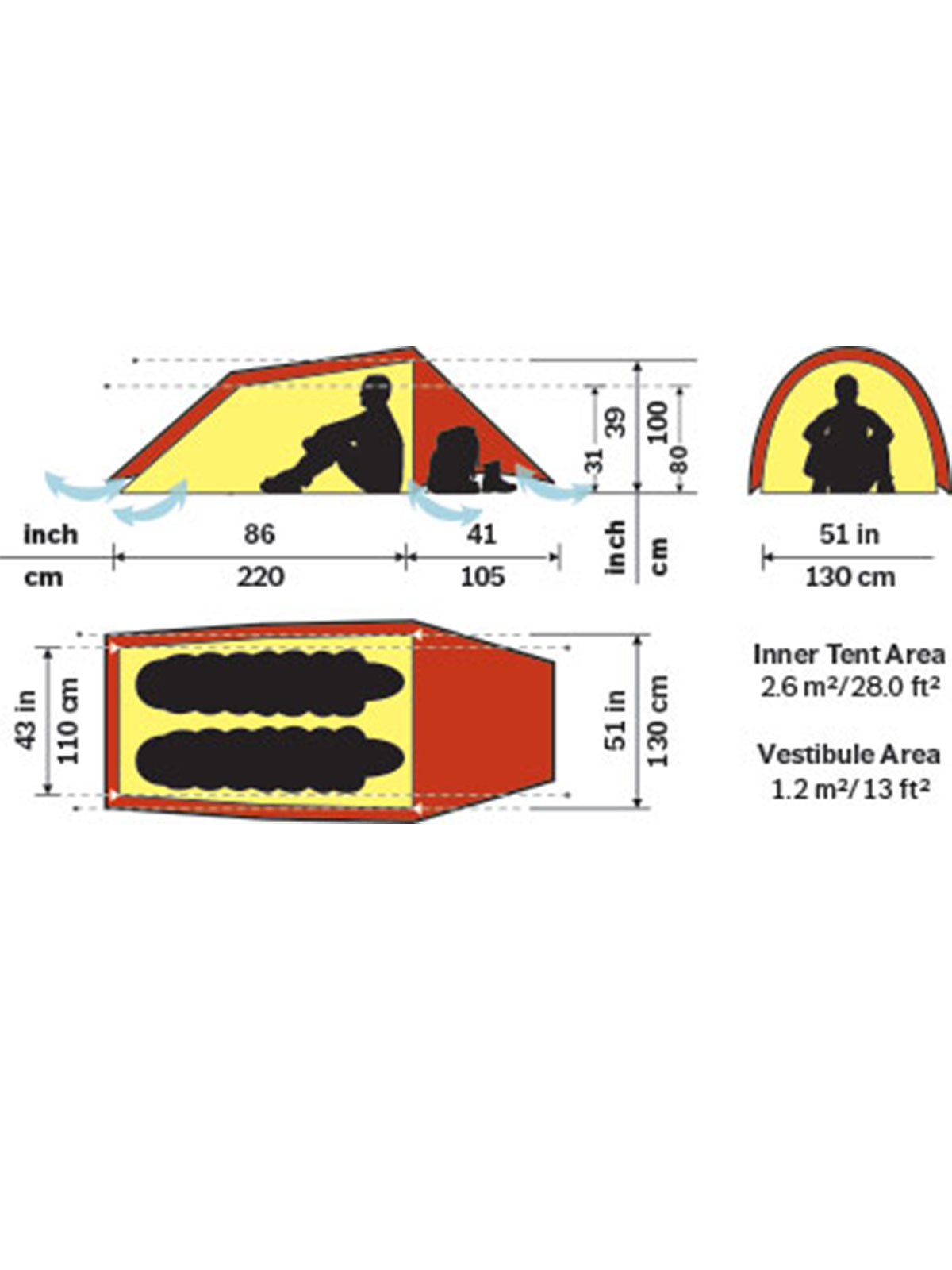

Another way we saved weight without compromising strength was to integrate the venting directly into the construction. Rather than adding vents, which would have added weight, we built in full time venting, either through a space between the outer tent and the ground in the Anjan, Anjan GT, Rogen and Niak models, or through incorporating protected mesh panels into the outer tent, as found in the Enan.

The result is a group of tents that are ideal for users who go out below tree line and in more protected terrain in the snow-free months of the year, and who demand light weight, but not at the expense of strength enough for the conditions they might encounter. For more on selecting the right tent for you, please see “Choosing the right Hilleberg tent.”